We offer a number of additional services to complement the wide range of products and custom-made solutions we can provide to original equipment manufacturers (OEMs) in the medical field.

Additional services for medical implants and instruments include passivation and surface finishing.

We also offer a number of laboratory and other services that are outlined below.

/ Passivation

Iron in the material and iron contamination created during fabrication is subject to rust and corrosion.

This surface iron is removed during passivation, resulting in a less chemically reactive surface.

Lincotek Medical also offering Citric and Nitric Passivation as per ASTM A967.

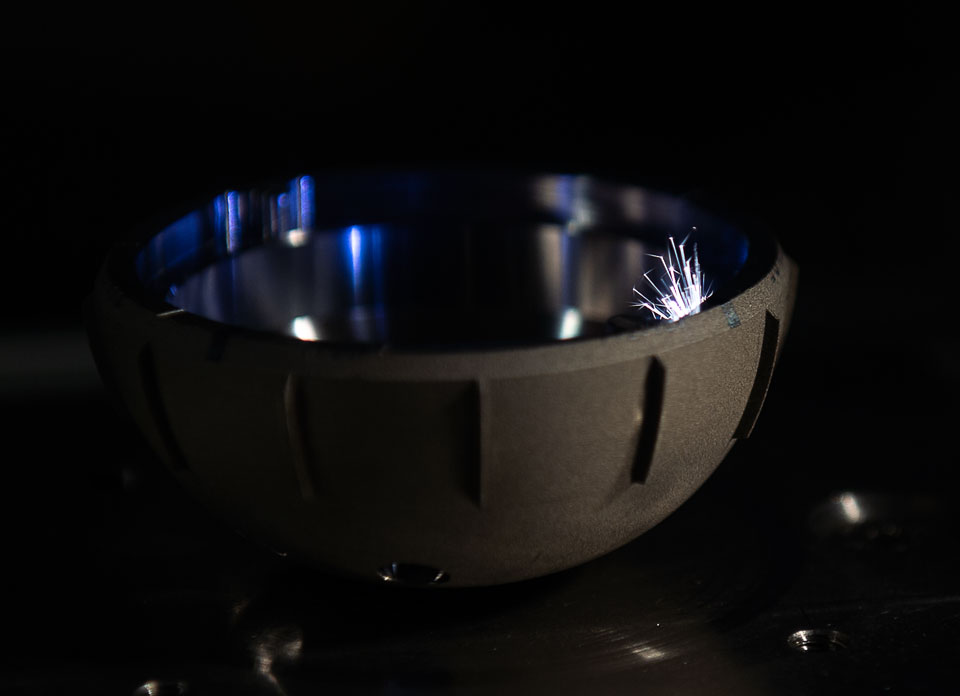

/ Surface finishing

The following finishing processes are available: sandblasting, tumbling, lapping, grinding, laser marking and welding.

In addition, chrome coating and epoxy resin color coding is available for medical implants.

/ Laboratory services

Our laboratories are under the Company quality certification (ISO 13485).

We provide the following type of characterization testing:

/ Other services

We can also offer you the following additional services:

These treatments are performed with extremely low impurity levels.

Contaminants are negligible as required for medical applications.